Compression garbage truck multi-way valve is also called a multi-way reversing valve. The reversing valve is to change the on-off relationship between different pipelines.

According to the number of working positions of the valve core in the valve body, it is divided into two, three, etc.;

According to the number of controlled channels, it can be divided into two-way, three-way, four-way, five-way, etc.;

According to the spool drive mode, it is divided into the manual, motor, electric, hydraulic and so on.

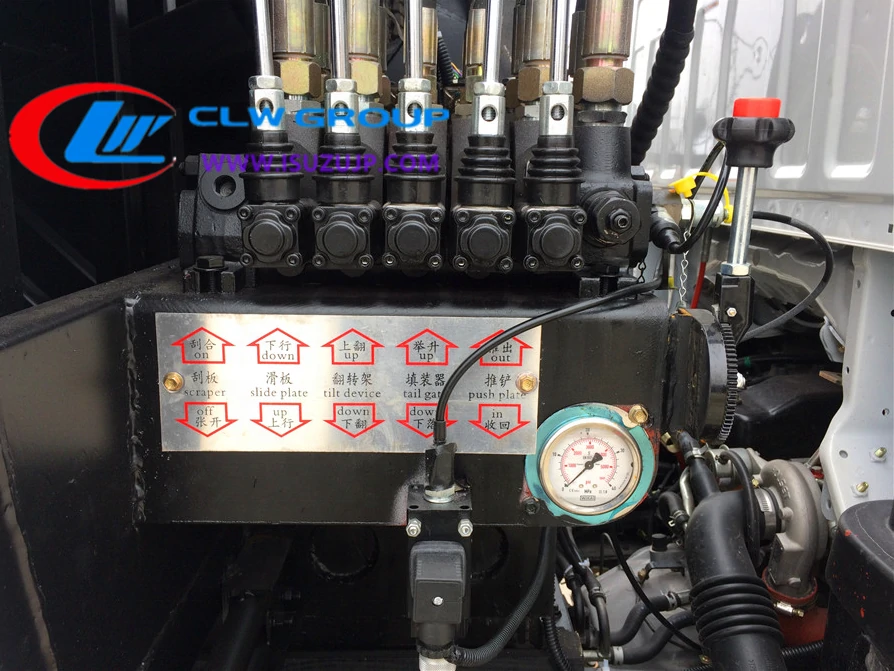

The multi-way reversing valve is a very common accessory in the Compression garbage truck. It is an indispensable accessory in the hydraulic system. For example, aerial work vehicles, garbage trucks, wrecker trucks and other models all rely on multi-way reversing valves. operate.

Electromagnetic reversing valves and manual multi-way reversing valves are the most used in Compression garbage trucks.

The electromagnetic reversing valve uses the on and off of the electromagnet to directly push the valve core to control the connection state of the oil port.

It is an automatic basic component used to control fluids and belongs to the actuator. That is a valve that controls the direction of hydraulic flow.

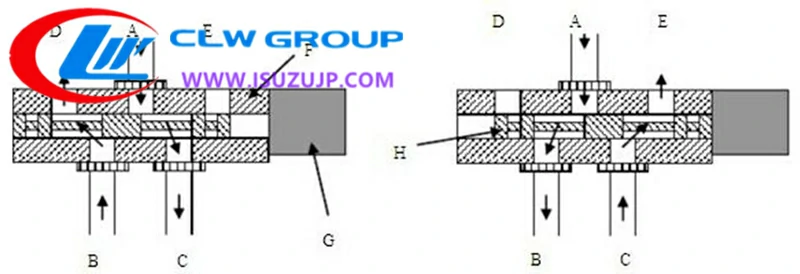

The working principle of the solenoid valve:

The electromagnetic reversing valve has a closed cavity, with through holes in different positions, each hole is connected to a different oil pipe, the middle of the cavity is a piston, and the two sides are two electromagnets. The magnet coil on which side is energized will attract the valve body. where?

By controlling the movement of the valve body to open or close different oil discharge holes, and the oil inlet hole is normally open, the hydraulic oil will enter different oil discharge pipes;

Then, the piston of the oil cylinder is pushed by the pressure of the oil, and the piston drives the piston rod, and the piston rod drives the mechanical device so that the mechanical movement is controlled by controlling the current on and off of the electromagnet.

The working principle diagram of the electromagnetic reversing valve:

The structural principle of electromagnetic reversing valve The basic working principle of electromagnetic reversing valve is the same. The different positions of the spool valve are controlled by the electromagnet to change the flow direction of the oil.

When the solenoid is de-energized, the spool valve is held in the neutral or initial position by a spring (except pulsed valves). Pushing the fault check button will move the spool of the spool valve.

Electromagnetic reversing valve features:

- The external leakage of the electromagnetic reversing valve is blocked, the internal leakage is easy to control, and the use is safe.

- The electromagnetic reversing valve system is simple, easy to maintain and low in price.

- The electromagnetic reversing valve has fast action, small power and light appearance.

Generally, on the Compression garbage truck, this electromagnetic reversing valve is combined with the electric control box to operate various operations. This is more flexible. The electric control operation box can be installed in the cab and other places so that it is easier to operate. For convenience.

For example, electromagnetic reversing valves are installed on water tank trucks and dust suppression vehicles, which can control the switch of pneumatic ball valves, etc.; electromagnetic reversing valves installed on aerial work vehicles can control the telescopic operation of the boom cylinder. See here, do you understand?