Product Name: BATTIONI PAGANI MEC 6500 Vacuum Pump Series

Item model number: MEC 6500 P LA DX UL D76 EM

Keywords: BATTIONI PAGANI vacuum pump MEC 6500 series

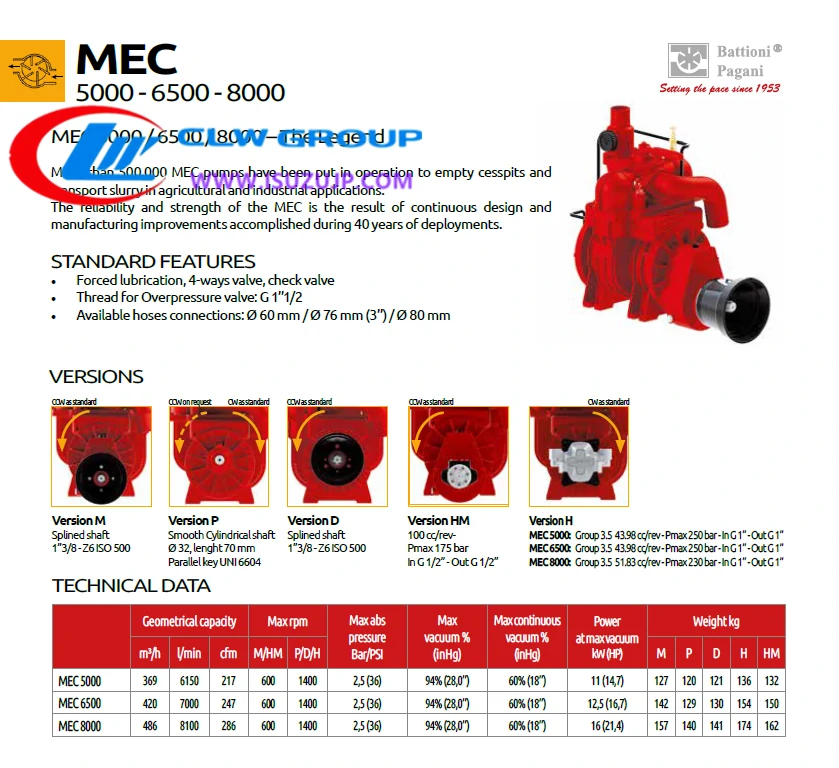

Keyword Description: The reliability and robustness of MEC pumps are the results of continuous design and production improvements over a 40-year lifespan.

product description:

More than 500,000 MEC pumps are used to empty cesspools and transport sewage for agricultural and industrial use.

The reliability and robustness of the MEC pump are the results of continuous design and production improvements over its 40-year lifespan.

The simple and practical design makes the MEC pump the reference product for emptying septic tanks in agricultural and municipal applications.

Standard equipment: forced lubrication, four-way valve, check valve.

Mec 6500 vacuum pump Specification:

| product | MEC 6500 | |

| geometric capacity | m3/H | 420 |

| L/min | 7000 | |

| cfm | 247 | |

| The number of revolutions (max.) | M/HM | 600 |

| P/D/High | 1400 | |

| pressure bar / PSI(max.) | 2.5 (36) | |

| Vacuum % (inHg)(max.) | 94% (28.0 inches) | |

| Continuous Vacuum % (inHg)(max.) | 60% (18 inches) | |

| Power vacuum kilowatts (HP)(max.) | 12.5 (16.7) | |

| WeightKG

| M. | 142 |

| p. | 129 | |

| D. | 130 | |

| H. | 154 | |

| HM. | 150 | |

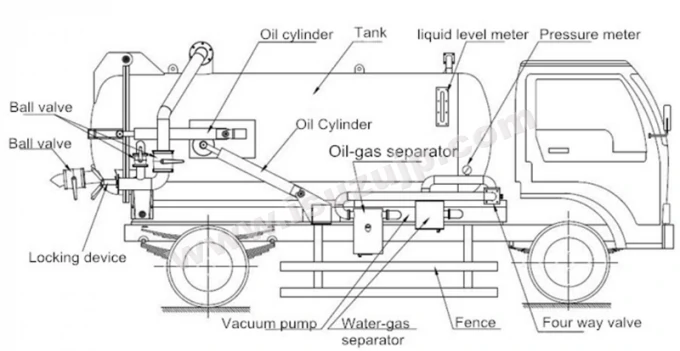

Sewage truck Vacuum pumps Structural design drawings:

Battioni Mec 5000 6500 8000 vacuum pump technical parameter:

Design drawing of sewer vacuum suction truck:

Installation and precautions for a vacuum truck suction pump for sewage trucks

- 1. The vacuum pump’s bottom surface is located on the bottom of both the suction and discharge top. The axis of power take-off’s output shaft determines the height of the vacuum pump. The principle and the schematic diagram are used to guide their installation.

- 2. The vacuum pump’s power is generated by the power take off at the power window of the automobile gearbox. The driver controls the handle from the cab and uses the power take off gear to combine the gearbox gear and the shift fork to drive the vacuum pump.

- 3. The schematic diagram shows how to install the double pump. To avoid interference, the intermediate joint between the four-way valve and the two pumps suction pipe and two pump oil and gasoline separator outlet pipes should be in the middle.

- 4. Installation of the oil and gasoline separator should not be done at high or low pressure. The oil outlet of an oil separator should not be lower than the oil inlet at either end of the pump.

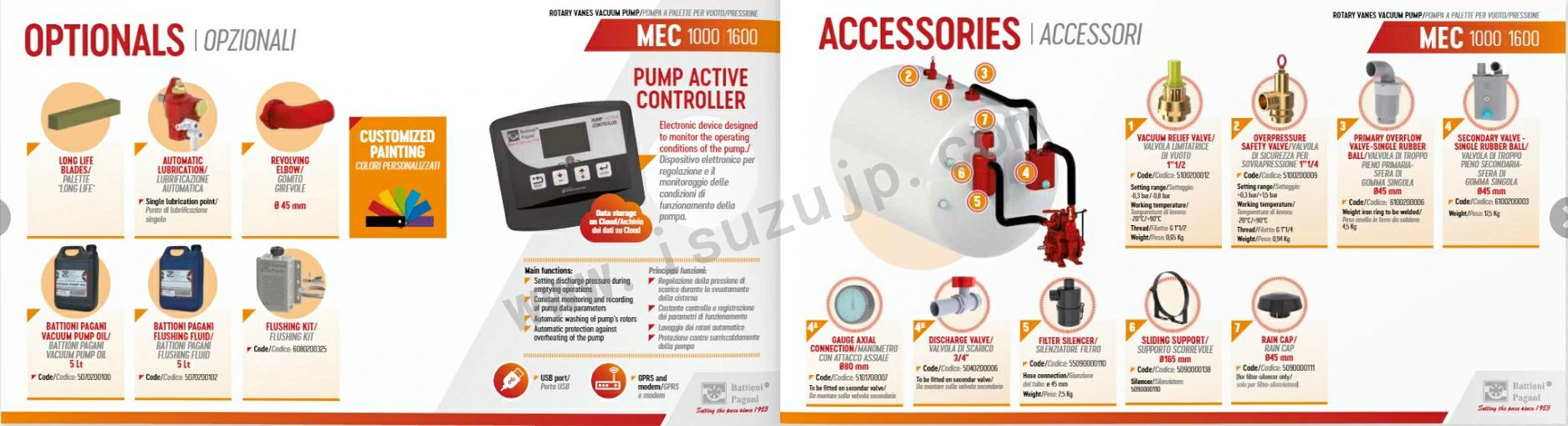

Other truck accessories catalog: